Interlining is one of the main materials in clothing production, and in modern clothing production, the use of adhesive interlining accounts for more than 90% of all interlining usage. Below is a detailed introduction to the adhesive lining.

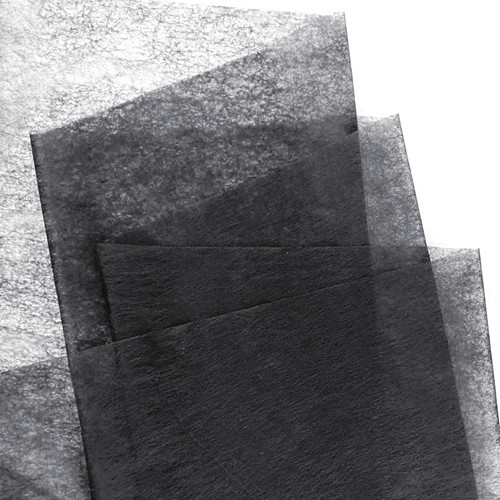

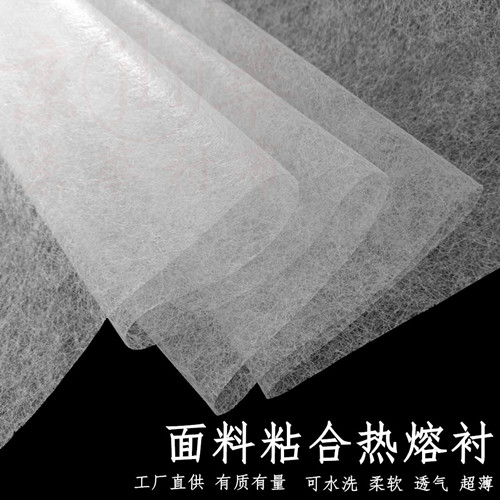

Adhesive lining, also known as hot melt adhesive lining. When using adhesive lining, it is necessary to heat up to bond the two surface fabrics together. The bonded fabric will become firm, beautiful, and elastic. When making clothing, it is necessary to choose different adhesive linings based on the specific requirements of the clothing.

Adhesive lining, also known as hot melt adhesive lining. When using adhesive lining, it is necessary to heat up to bond the two surface fabrics together. The bonded fabric will become firm, beautiful, and elastic. When making clothing, it is necessary to choose different adhesive linings based on the specific requirements of the clothing.

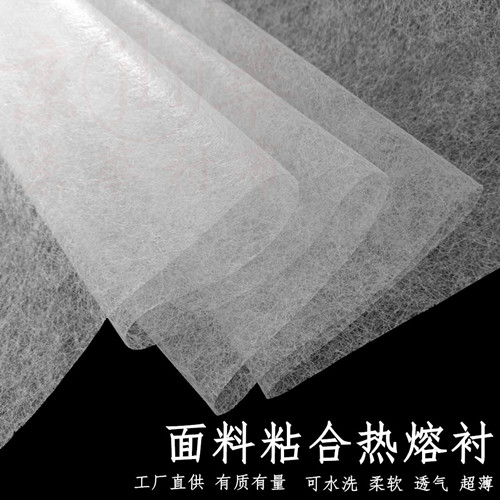

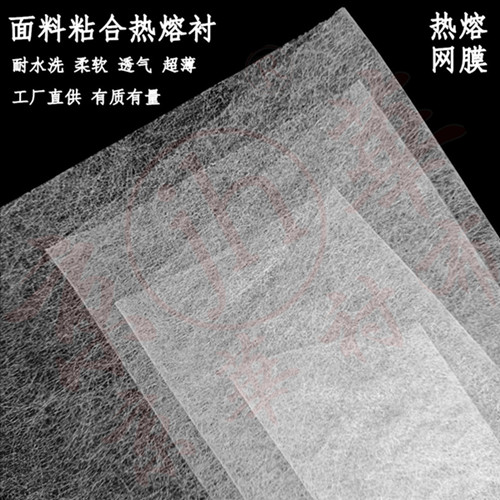

Generally speaking, the weight per square meter ranges from 10 grams to 25 grams, which we refer to as thin adhesive lining; A medium adhesive lining weighing between 25 grams and 40 grams per square meter is called a medium adhesive lining; A thick adhesive lining weighing between 40 grams and 60 grams per square meter is called a thick adhesive lining.

Generally speaking, the weight per square meter ranges from 10 grams to 25 grams, which we refer to as thin adhesive lining; A medium adhesive lining weighing between 25 grams and 40 grams per square meter is called a medium adhesive lining; A thick adhesive lining weighing between 40 grams and 60 grams per square meter is called a thick adhesive lining.

The function of adhesive lining is to make clothing straight and straight, making it look full and round.

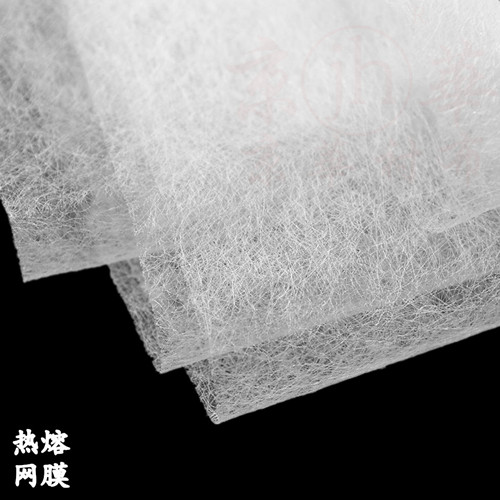

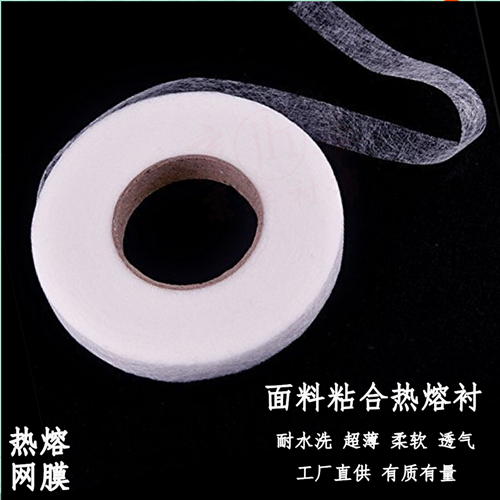

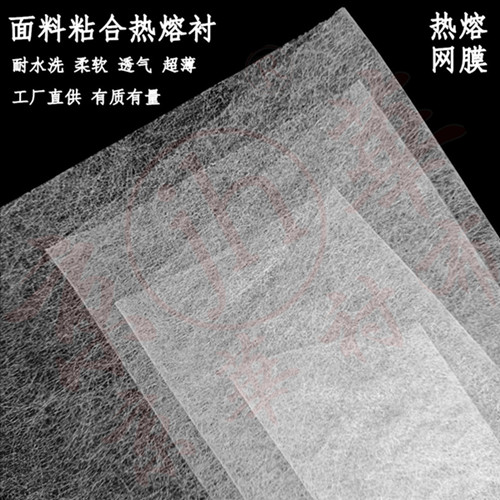

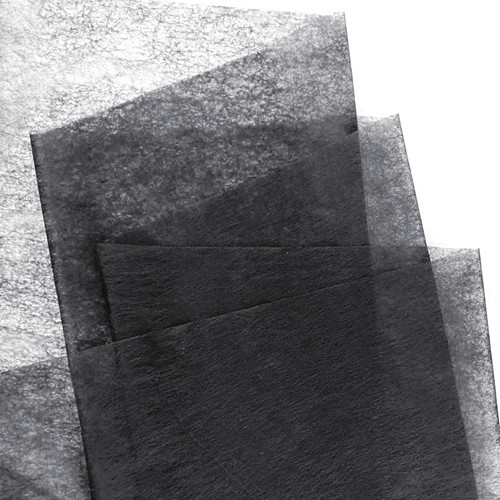

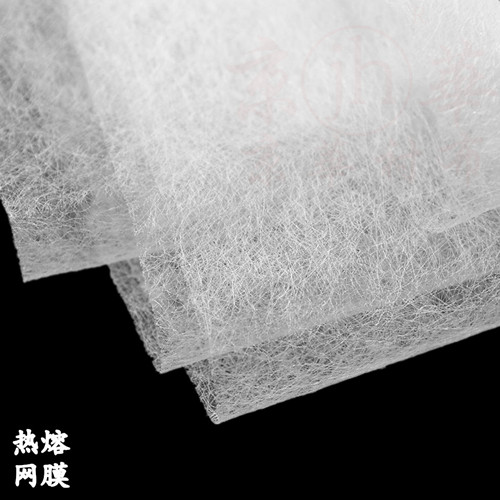

Usage of fabric lining: Place the fabric surface that needs to be bonded flat on the platform, lay the hot melt mesh film flat between the two layers of fabric that needs to be bonded, place a piece of paper or cloth on the top (to evenly heat the bottom to avoid damaging the fabric), and then start ironing. When ironing, adjust the temperature of the iron to high temperature without adding steam. Press the iron in the middle first, then press it around in order, and finally flip the fabric to the front before ironing it flat. When ironing, adjust the ironing temperature, pressure, and time according to the material of the fabric lining and surface fabric.