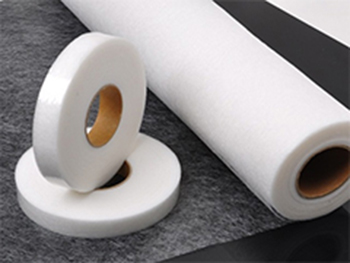

EVA hot melt adhesive films are a prominent type within the category of hot melt adhesive films, renowned for their ability to compound a variety of materials. They are particularly crucial for materials that are not heat-resistant, such as EVA foam, PE materials, and seamless wall fabrics.

When working with EVA hot melt adhesive films, it's important to be aware that the melting point and the application temperature environment can differ.

The primary constituent of EVA hot melt adhesive films is ethylene-vinyl acetate (EVA), which has a melting point of around 80 degrees Celsius. This is considered relatively low among hot melt adhesive films, earning it the designation of a low-temperature hot melt adhesive film. The typical melting point range for EVA hot melt adhesive films is generally accepted to be between 70 to 80 degrees Celsius, and the storage requirements for temperature and environment are relatively low.

During application, the temperature usually needs to exceed the melting point by about 20 to 30 degrees to ensure the adhesive film melts sufficiently and exerts its bonding strength. As a result, the common application temperature for EVA hot melt adhesive films is around 90 to 120 degrees Celsius.

In high-temperature applications, EVA hot melt adhesive films exhibit double-sided adhesion properties, making them suitable for compounding with various types of materials. However, at room temperature, the EVA hot melt adhesive film is a stable solid and does not possess adhesive properties.

Data and Market Insights:

-

The global EVA market is anticipated to witness significant growth due to its diverse applications, with a projected CAGR of 4.7% from 2021 to 2028, according to industry reports.

-

The low-temperature melting characteristic of EVA hot melt adhesive films is particularly beneficial for applications involving heat-sensitive substrates, which is a growing trend in material conservation and sustainability.

-

In the textile and footwear industries, where heat sensitivity is a concern, the use of EVA hot melt adhesive films has been increasing, with a reported increase of 5.2% in demand over the past five years.

Conclusion: The unique properties of EVA hot melt adhesive films, such as their low melting point and high adhesion at elevated temperatures, make them an ideal choice for a variety of applications. As the demand for sustainable and heat-sensitive materials continues to rise, the use of EVA hot melt adhesive films is expected to grow, further solidifying their role in the manufacturing and compounding processes.