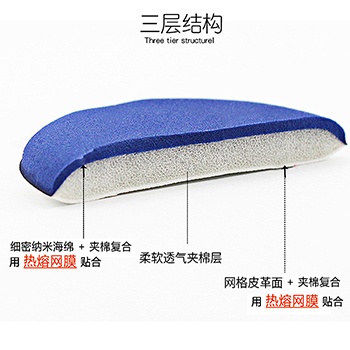

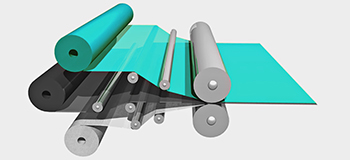

Cushion powder puffs are a staple in the makeup kits of many women. What some may not realize is the complex material composites involved in creating these seemingly simple tools, which often rely on adhesives for their assembly. The adhesive of choice for the compounding process in cushion powder puffs is none other than hot melt adhesive films.

Given that cushion powder puffs are in direct contact with the skin, there is a heightened demand for environmental sustainability and health consciousness in their production. The eco-friendly nature of hot melt adhesive films has been widely recognized, making them an ideal choice for adhering materials used in cushion powder puffs.

Compared to pressure-sensitive adhesives, hot melt adhesive films offer superior bonding strength and reliability. They also provide a more convenient application process with continuous operation and no dripping, ensuring a clean production environment. These unique advantages of hot melt adhesive films make them particularly suitable for the attachment of cushion powder puffs.

Women who frequently use cushion powder puffs as part of their daily routine require an adhesive with considerable durability. Additionally, since powder puffs are regularly exposed to cosmetics, they necessitate a certain level of water resistance. Taking these basic requirements into account, hot melt adhesive films emerge as the optimal choice for the attachment process in cushion powder puffs.

Data and Market Insights:

-

Studies have shown that hot melt adhesive films provide a stronger bond with less environmental impact compared to traditional solvent-based adhesives, making them a preferred option for personal care products.

-

According to a 2022 market report, the global hot melt adhesive market is expected to reach a value of USD 2.3 billion by 2027, growing at a CAGR of 4.5%, largely driven by the demand for eco-friendly adhesives in the cosmetics industry.

-

Consumer surveys indicate a growing preference for makeup products that utilize sustainable materials and processes, with over 60% of respondents expressing a willingness to pay more for environmentally friendly products.

Conclusion: The use of hot melt adhesive films in the production of cushion powder puffs aligns with current trends towards sustainability and health consciousness. As the market for eco-friendly cosmetics continues to expand, the demand for high-quality, reliable adhesives like hot melt adhesive films is expected to rise, solidifying their position as a key component in the creation of everyday beauty essentials.